A laser cleaner uses a high-energy laser beam to vaporize or remove unwanted surface layers such as rust, paint, or oil residues. The beam interacts with contaminants by heating them rapidly, causing a process known as ablation. This removes the unwanted layer without damaging the substrate underneath. The method is highly selective — it targets only the unwanted material, leaving the original surface clean, smooth, and ready for subsequent processing.

Unlike conventional cleaning techniques such as sandblasting or chemical treatments, the laser cleaner operates through a contactless process. This eliminates the use of abrasives, solvents, and water, providing an environmentally responsible cleaning method. The precision of the laser allows operators to control intensity and depth, ensuring consistent results even on complex geometries.

How the Laser Cleaner Works

The mechanism behind a laser cleaner lies in the interaction of light and matter. When a focused laser beam strikes a contaminated surface, it transfers energy to the contaminants. The contaminants absorb this energy and undergo rapid thermal expansion. Depending on the material’s properties, this can lead to direct vaporization, mechanical ejection, or plasma formation, all contributing to surface cleaning.

Different power levels and wavelengths are used based on the application. Low-power laser cleaners are ideal for delicate cleaning tasks such as removing oxides from precision components, while high-power units are suitable for heavy-duty operations like rust removal from large steel structures or paint stripping from aircraft panels.

Modern laser cleaner systems often include automated scanning heads, handheld guns, and advanced control panels, allowing operators to adjust parameters such as pulse frequency, beam diameter, and scanning speed. This flexibility ensures optimal cleaning performance across different materials and contamination types.

Industrial Applications of Laser Cleaner

The versatility of a laser cleaner extends across multiple industries. In manufacturing plants, it is used for pre-welding and pre-coating surface preparation, ensuring stronger bonds and better coating adhesion. Automotive workshops rely on it to clean engine parts, molds, and tools, enhancing product quality and durability.

In the aerospace industry, laser cleaning helps remove paint layers from aircraft without affecting the lightweight aluminum or composite surfaces underneath. Similarly, shipyards employ laser cleaners to remove rust and old coatings from large metal hulls, improving efficiency and reducing downtime.

The laser cleaner also finds applications in cultural heritage restoration, where it gently removes dirt, corrosion, and biological growth from sculptures, monuments, and historical artifacts. The precision and non-invasive nature of laser cleaning make it ideal for preserving delicate surfaces.

Environmental and Operational Impact

The adoption of a laser cleaner contributes to a cleaner and safer work environment. Traditional cleaning methods often involve hazardous chemicals or produce large volumes of waste material. Laser cleaning, on the other hand, generates minimal waste — mainly dust and vaporized particles that can be easily collected using extraction systems.

Operators benefit from reduced exposure to harmful substances, while companies save on the costs associated with chemical disposal and environmental compliance. The efficiency of laser cleaning also leads to shorter maintenance cycles and improved productivity, making it a sustainable choice for long-term operations.

The precise control offered by a laser cleaner minimizes material loss and extends the lifespan of expensive industrial components. By removing only the surface impurities, it preserves the integrity of metals and alloys, ensuring that equipment and parts maintain their original properties even after repeated cleaning.

Integration in Modern Production Lines

With advancements in automation, the laser cleaner is increasingly being integrated into robotic and automated production lines. Robots equipped with laser cleaning heads can perform continuous, high-speed surface treatment on complex components. This automation improves consistency and eliminates human error, especially in high-volume industrial environments.

In factories that rely on lean manufacturing principles, laser cleaners enhance process efficiency by reducing preparation time and eliminating secondary cleaning steps. The equipment can be programmed to operate at specific angles and intensities, adapting to different product designs seamlessly.

The compact design of handheld laser cleaner systems also makes them suitable for on-site maintenance and repair tasks. Field engineers can carry portable units to clean machinery, pipelines, and metal structures without the need for disassembly. This mobility brings flexibility and cost savings to industries that operate in dynamic or remote environments.

Cost Efficiency and Maintenance

While the initial investment in a laser cleaner might appear significant, the long-term cost savings are considerable. The absence of consumables such as sand, chemicals, or cleaning agents drastically reduces operational expenses. Additionally, minimal wear and tear on equipment components lead to lower maintenance costs.

The energy efficiency of laser technology contributes further to cost control. Modern laser cleaners use fiber lasers, known for their high electrical efficiency and long operational life. With proper maintenance and calibration, these systems can function reliably for years without significant degradation in performance.

Maintenance of a laser cleaner typically involves inspecting optical components, cleaning the lens, and ensuring proper cooling system operation. Regular preventive maintenance ensures that the laser maintains consistent output and precision, making it a dependable tool in industrial workflows.

Safety Considerations

Operating a laser cleaner requires adherence to safety protocols to protect personnel and equipment. Since lasers produce high-energy beams, proper protective eyewear and shielding must be used to prevent exposure. Many laser cleaning systems come with built-in safety features such as motion sensors, interlocks, and emergency shut-off controls.

Training operators on correct handling, beam control, and material-specific parameters ensures safe and efficient usage. Following manufacturer guidelines and safety standards promotes a secure work environment while maximizing the cleaning system’s performance.

Market Demand and Future Prospects

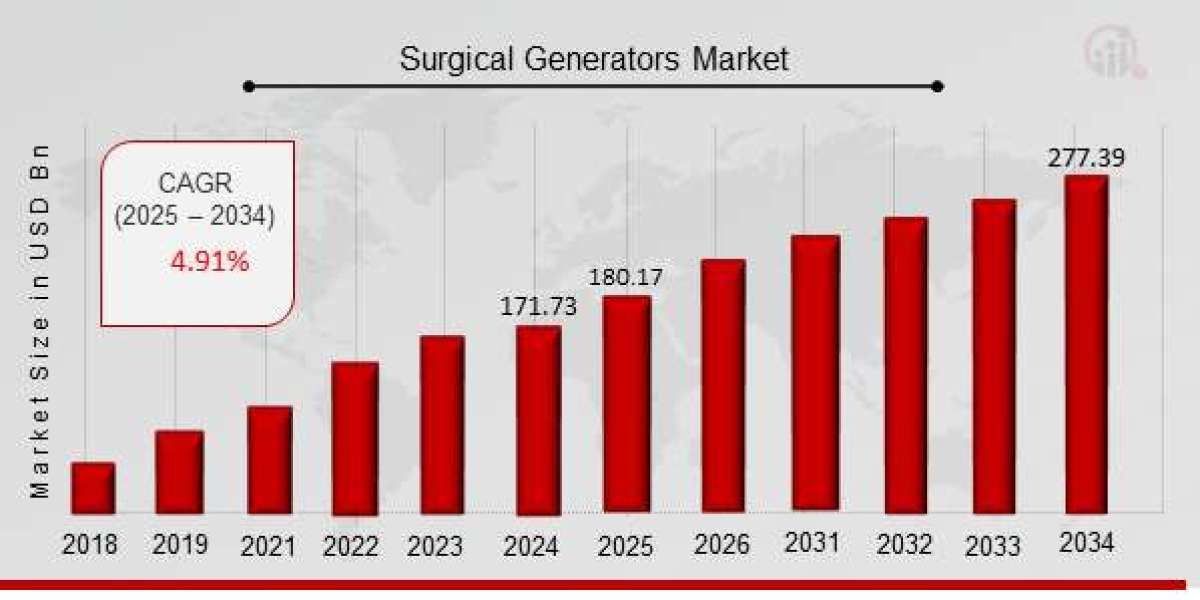

The global demand for laser cleaner technology is growing rapidly due to the industry’s focus on sustainability and precision. As industries transition away from chemical and abrasive methods, laser cleaning stands out as the preferred solution for surface preparation. Manufacturers are continually developing more compact, powerful, and energy-efficient systems to meet the evolving needs of modern production.

The increasing emphasis on eco-friendly practices and regulatory compliance has accelerated the shift toward laser-based cleaning. With advancements in automation and digital control, future laser cleaners will likely feature smarter interfaces, AI-driven parameter adjustments, and integrated process monitoring for consistent results.

Final Thoughts

The laser cleaner represents the evolution of industrial cleaning — a technology that combines precision, speed, and environmental responsibility. From removing rust on steel to restoring delicate artifacts, its versatility makes it a cornerstone of modern surface treatment solutions. As industries continue to seek efficiency and sustainability, laser cleaning stands ready to redefine how surfaces are maintained and prepared for the future.