A laser cleaner machine is a high-tech tool designed for non-contact surface cleaning. It utilizes focused laser beams to remove rust, paint, oxide layers, oil, and other contaminants from a wide range of materials—such as metal, stone, plastic, or even delicate surfaces—without damaging the base layer.

This innovative technology is increasingly replacing traditional abrasive methods like sandblasting and chemical solvents, offering a safer, more efficient, and environmentally friendly solution for industrial cleaning tasks.

⚙️ How Does a Laser Cleaner Machine Work?

Laser cleaning is based on the principle of laser ablation. A high-energy pulsed laser beam is directed onto the surface, where it:

Absorbs into contaminants like rust or paint

Causes rapid thermal expansion and vaporization of the layer

Leaves the underlying surface intact

Since different materials absorb laser energy at different rates, precision cleaning can be achieved without damage to sensitive substrates.

? Key Features of a High-Quality Laser Cleaner Machine

| Feature | Benefit |

|---|---|

| Adjustable Power Output | Customizable for different materials and coatings |

| Handheld & Portable Options | Flexible for on-site maintenance tasks |

| Air Cooling or Water Cooling | Efficient temperature management during operation |

| No Consumables | Low operating costs and minimal maintenance |

| Eco-Friendly Design | No use of chemicals or abrasive media |

| Real-Time Monitoring | Enhances precision and reduces over-processing |

? Applications of Laser Cleaner Machines Across Industries

1. Automotive Industry

Removes rust from engine parts, chassis, and molds

Cleans welding joints before/after processing

2. Aerospace & Aviation

Prepares surfaces for bonding and coating

Cleans delicate components without structural damage

3. Electronics & Precision Engineering

Removes fine oxides from electrical contacts

Ensures ultra-clean surfaces for high-performance circuits

4. Cultural Heritage & Restoration

Removes dirt and biological growth from sculptures, stonework, and murals

Allows for layer-by-layer cleaning to preserve details

5. Shipbuilding & Railways

De-rusting of ship hulls and rail components

Paint and coating removal without affecting the substrate

? Why Industries Are Switching to Laser Cleaning Technology

✅ Precision & Selectivity

Laser cleaning offers micrometer-level accuracy, which is ideal for delicate parts and complex geometries.

✅ Cost Efficiency

While the initial investment can be higher than traditional systems, the absence of consumables, low maintenance, and long lifespan result in a lower total cost of ownership.

✅ Safety and Environmental Benefits

No harmful chemicals

No dust or secondary waste

Less noise and operator exposure

✅ Automation & Integration

Modern machines support robotic arms and CNC systems, making them suitable for mass production and smart factories.

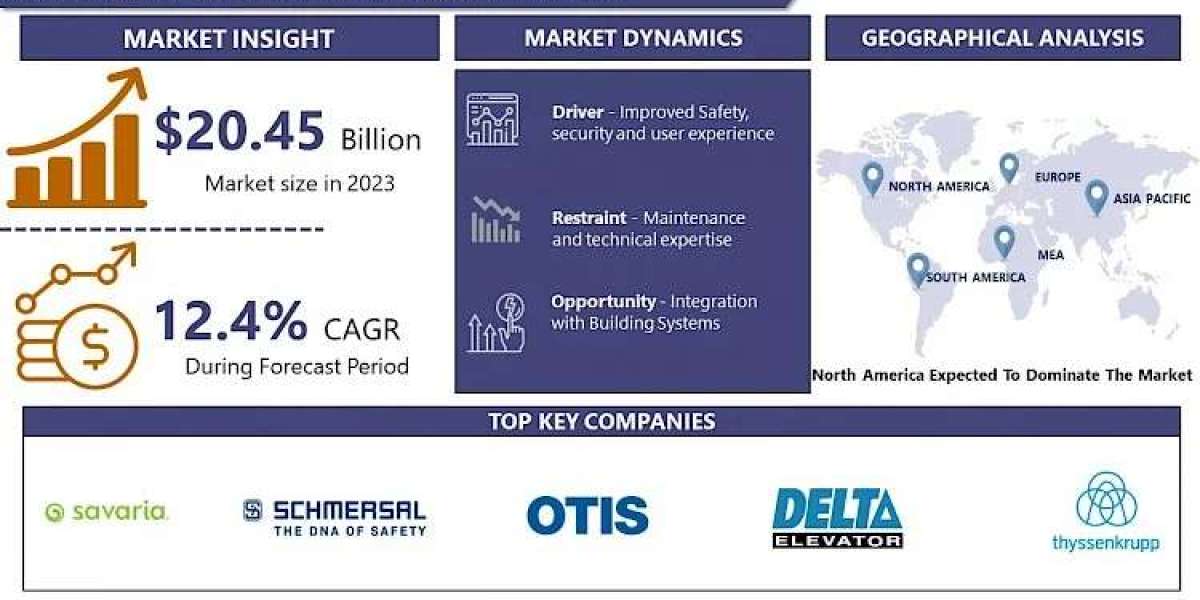

? Market Growth and Industry Trends

According to industry insights, the global laser cleaning market is expected to grow at a compound annual growth rate (CAGR) of 9–12% over the next five years. This growth is driven by:

Increasing automation in manufacturing

Demand for environmentally friendly cleaning solutions

Stricter regulations on solvent-based methods

? Frequently Asked Questions (FAQs)

Q1: Is laser cleaning safe for all materials?

A: Yes, when correctly configured, it is safe for metals, stone, ceramics, plastics, and even delicate artworks. However, material testing is always recommended.

Q2: How much maintenance does a laser cleaner machine require?

A: Minimal. Most machines require only basic lens cleaning and system checks. There are no abrasive parts to replace.

Q3: Can it be used outdoors or on large structures?

A: Yes, portable and handheld models are designed for on-site cleaning of bridges, pipelines, ships, and more.

Q4: What power rating should I consider?

A:

50–100W: Ideal for delicate precision cleaning

200–500W: Suitable for industrial rust and paint removal

1000W+: Heavy-duty cleaning and large surface areas

Q5: How does laser cleaning compare to sandblasting?

A: Laser cleaning is cleaner, quieter, and far more precise. Unlike sandblasting, it doesn't produce dust clouds or degrade the base material.

?️ Technical Considerations Before Buying a Laser Cleaner Machine

Before making a purchase, consider these key factors:

Laser Type: Fiber lasers are the most common due to durability and efficiency

Pulse Width: Short-pulse lasers are better for thermal-sensitive tasks

Mobility: Decide between portable (handheld) or stationary systems

Cooling System: Air-cooled for mobility; water-cooled for continuous heavy-duty use

Power Supply and Safety Certification: Ensure compatibility and compliance with regional standards

? Common Industries Adopting Laser Cleaning

| Industry | Common Use |

|---|---|

| Aerospace | Composite prep, paint removal |

| Automotive | Weld prep, de-rusting |

| Foundries | Mold cleaning, oxide removal |

| Oil & Gas | Pipeline maintenance, corrosion control |

| Electronics | PCB prep, micro-cleaning |

| Art & Conservation | Restoration, graffiti removal |

? Expert Insight

Industrial engineers and materials scientists now widely recommend laser cleaning as part of a sustainable manufacturing ecosystem. As digital factories grow, contactless technologies like laser cleaning are expected to play a pivotal role in automating surface treatment with minimal downtime and environmental footprint.

? Quick Tips for First-Time Buyers

Start with a demo: Evaluate performance on your specific materials

Check warranty and support: After-sales service is crucial for high-tech equipment

Training matters: Ensure your team receives proper operation and safety guidance

Look for CE, ISO, or FDA certifications (depending on your region)

Ask about laser source life: Top models offer up to 100,000+ hours of laser life