Introduction

The demand for advanced cooling solutions has significantly grown due to rising industrial activities, increasing urbanization, and the expanding use of high-performance machines, automobiles, and electronics. Radiant Coolant is one such solution that has found applications in various sectors such as automotive, electronics, HVAC (Heating, Ventilation, and Air Conditioning) systems, and industrial machinery. It plays a crucial role in managing temperature and preventing overheating, ensuring the smooth operation of engines, machinery, and equipment. A Radiant Coolant Manufacturing Plant can be a profitable business opportunity, especially in industries focusing on sustainability and energy-efficient systems. This Radiant Coolant Manufacturing Plant Project Report provides an in-depth analysis of the market trends, manufacturing processes, raw materials, plant layout, and financial projections for establishing a radiant coolant production unit.

Market Overview and Demand for Radiant Coolant

The demand for radiant coolants is driven by several factors:

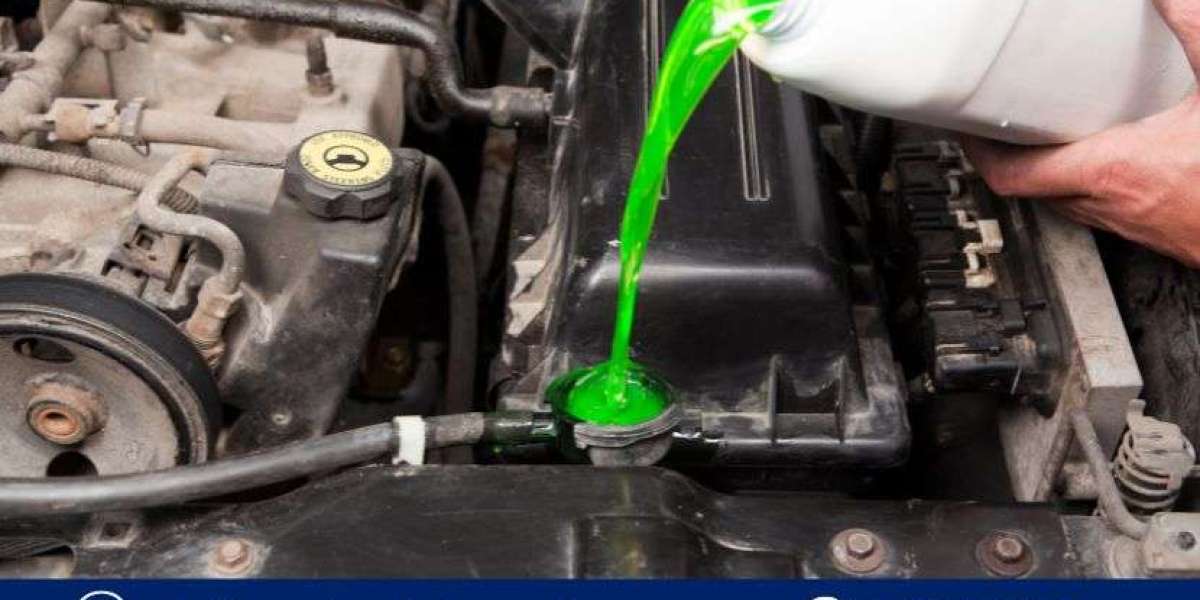

Automotive Industry: With the growing number of vehicles on the road, including high-performance and electric vehicles, the need for efficient coolant systems has surged. Radiant coolants are used to prevent engine overheating and maintain optimum temperature in engines and HVAC systems.

Industrial Machinery: Industrial machinery, such as compressors, turbines, and generators, requires advanced cooling solutions to prevent excessive heat buildup that can reduce performance or cause damage. Radiant coolants offer improved thermal efficiency, making them suitable for such heavy machinery.

Electronics and Power Systems: As electronic devices become smaller and more powerful, there is a growing need for effective cooling systems to prevent components from overheating. Radiant coolants, with their superior heat transfer properties, are used in power systems, cooling units, and electronics.

Energy-Efficiency and Sustainability: As businesses and industries push toward energy efficiency, radiant coolants provide an eco-friendly and sustainable solution. These coolants help in reducing the energy consumption of cooling systems, making them highly sought after in green building projects and eco-conscious sectors.

Regulatory Compliance and Technological Advancements: Governments and regulatory bodies across the globe are promoting the use of energy-efficient and environmentally friendly cooling solutions. New developments in chemical formulations have resulted in the creation of coolants that offer better heat transfer, longer shelf life, and reduced environmental impact.

Get a Free Sample Report with Table of Contents@

Key Considerations for Setting Up a Radiant Coolant Manufacturing Plant

1. Location Selection

The location of your manufacturing plant is crucial to the operational success of the project. Key factors to consider include:

Proximity to Raw Materials: The primary raw materials for radiant coolant production include chemicals like ethylene glycol, propylene glycol, water, and other additives. Choose a location near suppliers of these materials to minimize transportation costs.

Access to Transportation Infrastructure: The plant should be situated near major highways, railroads, and ports for easy distribution of finished products and the receipt of raw materials.

Labor Availability: Skilled labor is essential for managing production processes and quality control. Ideally, the location should have access to a trained workforce in chemical manufacturing, packaging, and logistics.

Regulatory Compliance: Select a location that adheres to local environmental and safety regulations. These include waste disposal standards, air and water quality controls, and worker safety.

2. Plant Design and Layout

The design of the manufacturing plant should promote efficiency, safety, and scalability. The key sections in the layout of the plant include:

Raw Material Storage: A dedicated area to store the base chemicals (propylene glycol, ethylene glycol, water, etc.) should be well-ventilated, fireproof, and comply with safety standards to minimize the risk of chemical spills or reactions.

Production Area: This area should house equipment for mixing, blending, and chemical reactions needed to produce radiant coolants. Key equipment will include mixers, heat exchangers, and reactors.

Quality Control Laboratory: A laboratory to test raw materials, in-process samples, and finished coolants to ensure they meet industry standards for quality, purity, and performance.

Packaging Section: The finished radiant coolant needs to be packaged efficiently into bottles, drums, or bulk containers for distribution. This area will require automatic packaging lines, labeling, and sealing machines.

Waste Disposal Section: Managing chemical waste generated during production is essential. The plant should include a waste treatment system that complies with environmental regulations.

Warehouse/Storage: A well-organized storage area to store raw materials, in-process products, and finished products is required. Proper shelving and temperature control should be maintained.

3. Manufacturing Process

The production of radiant coolant involves several key steps:

Formulation of Coolant Mixture: The primary ingredients for radiant coolant include ethylene glycol or propylene glycol, water, corrosion inhibitors, and anti-foaming agents. The exact formulation depends on the specific requirements of the coolant and the target market.

Mixing: The raw materials are blended in large mixing tanks to create a homogeneous coolant mixture. The mixing process must be carefully monitored to ensure that the right chemical ratios are maintained for optimal heat transfer and anti-corrosive properties.

Chemical Reaction (if necessary): Some formulations may require a chemical reaction or additional processing steps, such as the addition of specific inhibitors or stabilizers, to improve the thermal properties or extend the coolant’s lifespan.

Filtration and Purification: Once the coolant mixture is ready, it is filtered to remove any impurities, solid particles, or air bubbles that may affect its performance or stability.

Quality Control Testing: Samples of the coolant are taken to the quality control laboratory for testing. Key parameters such as freezing point, boiling point, pH level, viscosity, and thermal conductivity are checked.

Packaging: After successful testing, the coolant is packaged into appropriate containers based on the market demand. The packaging process involves filling, sealing, labeling, and boxing for shipment.

Storage and Distribution: The finished products are stored in a controlled environment to maintain product quality before being distributed to customers through a well-organized distribution network.

Key Equipment Used in the Manufacturing Process:

- Mixing Tanks: For blending raw materials into a uniform coolant mixture.

- Heat Exchangers: Used to control the temperature of the coolant during the production process.

- Filtration Systems: To remove impurities from the coolant mixture.

- Packaging Machines: For filling, sealing, and labeling coolant containers.

- Quality Control Instruments: For testing the thermal properties, viscosity, and chemical stability of the coolant.

4. Raw Materials and Supply Chain Management

The primary raw materials for manufacturing radiant coolants include:

- Ethylene Glycol or Propylene Glycol: These are the key components in most coolant formulations. They provide the base for heat transfer.

- Water: Used to dilute the glycol and create the desired viscosity for the coolant.

- Corrosion Inhibitors: These additives prevent rust and corrosion in cooling systems.

- Antifreeze and Antifoam Agents: These chemicals enhance the coolant’s ability to resist freezing in low temperatures and reduce foam formation during operation.

Ensuring a steady and reliable supply of high-quality raw materials is essential for the efficient operation of the plant. Establishing strong relationships with suppliers and maintaining an effective inventory management system will help in managing costs and minimizing production disruptions.

5. Environmental and Safety Compliance

Radiant coolant manufacturing involves handling chemicals, and thus the plant must adhere to stringent environmental and safety standards:

Chemical Safety: Proper safety protocols must be followed when handling hazardous chemicals, including the use of personal protective equipment (PPE), emergency response procedures, and training for workers.

Waste Management: Any waste products, such as leftover chemicals or packaging materials, must be disposed of in accordance with local environmental regulations. Recycling and reuse should be prioritized where possible.

Emission Control: The plant should be equipped with ventilation systems and filtration units to control emissions and prevent chemical contamination in the surrounding environment.

Fire and Hazard Prevention: Given the flammable nature of some coolant ingredients, the plant should have fire prevention measures, including fire extinguishers, sprinkler systems, and designated fire exits.

6. Quality Control and Testing

Quality control is critical in ensuring that the radiant coolant produced meets industry standards for performance and safety. The following tests are typically conducted:

- Viscosity Testing: To determine the flow characteristics of the coolant.

- Freezing and Boiling Point Testing: To ensure the coolant performs under extreme temperature conditions.

- Corrosion Resistance Testing: To check the coolant’s ability to protect metal surfaces in engines and cooling systems.

- Thermal Conductivity Testing: To ensure the coolant has the required heat transfer properties for efficient cooling.

- Stability Testing: To verify that the coolant remains stable over time without degradation.

7. Financial Planning and Investment

Setting up a radiant coolant manufacturing plant requires substantial capital investment. Key financial considerations include:

- Capital Investment: The cost of land, building the plant, and purchasing the necessary equipment.

- Operating Costs: These include raw materials, labor, utilities (electricity, water), maintenance, and packaging.

- Revenue Projections: Forecasting revenue based on production capacity, pricing, and market demand for radiant coolants.

- Return on Investment (ROI): Calculating the ROI to determine the financial viability of the plant and break-even points.

8. Marketing and Distribution Strategy

To succeed in the competitive coolant market, the plant should have a strong marketing and distribution strategy. Key elements to consider include:

- Branding: Positioning the product as a high-quality, eco-friendly, and energy-efficient solution for automotive, industrial, and electronics sectors.

- Target Market: The primary customers for radiant coolants include automotive manufacturers, industrial machine operators, and large-scale HVAC contractors.

- Distribution Channels: The plant can establish a direct sales force, work with distributors, or sell through retail outlets for broad market reach.

Media Contact

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au