Among these breakthroughs, Polypropylene (PP) spunbond nonwoven fabric stands out as a versatile material with exceptional capabilities. Its unique characteristics and diverse applications have made it a cornerstone in numerous industries, from healthcare and hygiene to agriculture and packaging. This article delves into the intricacies of Spunbond non woven fabric exporters in Gujarat, exploring its manufacturing process, properties, applications, and the significant role it plays in the market. We'll also touch upon the thriving hub of production in Gujarat, India, and the key players contributing to its growth.

The Genesis of ShieldWeave: Unraveling the Spunbond Process

The magic behind PP spunbond nonwoven fabric lies in its unique manufacturing process. Unlike traditional woven fabrics, which involve interlacing yarns, spunbond nonwovens are created directly from polymer filaments. The process typically begins with the melting of polypropylene (PP) resin. This molten polymer is then extruded through spinnerets, which are essentially fine nozzles that create continuous filaments. These filaments are then drawn, either by air jets or mechanical rollers, to increase their strength and reduce their diameter. The drawn filaments are subsequently laid down on a moving conveyor belt, forming a web-like structure. This web is then bonded together, usually through thermal bonding (using heat and pressure), chemical bonding (using adhesives), or mechanical bonding (using needles or water jets). The resulting fabric is a strong, durable, and versatile material known as PP spunbond nonwoven fabric. The specific characteristics of the fabric, such as its weight, thickness, strength, and porosity, can be customized by adjusting the parameters of the manufacturing process, such as the filament diameter, bonding method, and web formation technique.

Unveiling the Extraordinary Properties

The appeal of PP spunbond nonwoven fabric is rooted in its exceptional properties, which set it apart from traditional textiles:

- Strength and Durability: The spunbond process creates a fabric with high tensile strength and tear resistance, making it ideal for applications where durability is paramount.

- Breathability: The fabric's nonwoven structure allows for excellent air permeability, making it comfortable and suitable for applications such as medical gowns and hygiene products.

- Water Resistance: PP is inherently hydrophobic, making spunbond nonwoven fabric resistant to water and moisture. This property is crucial in applications such as protective apparel and packaging.

- Chemical Resistance: PP exhibits good resistance to a wide range of chemicals, making the fabric suitable for use in demanding environments.

- Softness and Drapeability: Despite its strength, the fabric can be made soft and flexible, enhancing its comfort and usability.

- Recyclability: Polypropylene is a recyclable thermoplastic polymer, contributing to the sustainability of PP spunbond nonwoven fabrics.

- Cost-Effectiveness: Compared to other textile materials, PP spunbond nonwoven fabric offers a favorable cost-to-performance ratio.

Applications Across Industries: A Testament to Versatility

The adaptability of PP spunbond nonwoven fabric is evident in its widespread applications across various sectors:

- Healthcare: It is extensively used in medical applications, including surgical gowns, drapes, masks, caps, shoe covers, and sterilization wraps, due to its protective barrier, breathability, and hygiene properties.

- Hygiene: In the hygiene industry, it is a key component in diapers, sanitary napkins, and other absorbent products, providing softness, liquid barrier properties, and comfort.

- Agriculture: It plays a vital role in agriculture as crop covers, weed control fabrics, and greenhouse shading materials, protecting crops and improving yields.

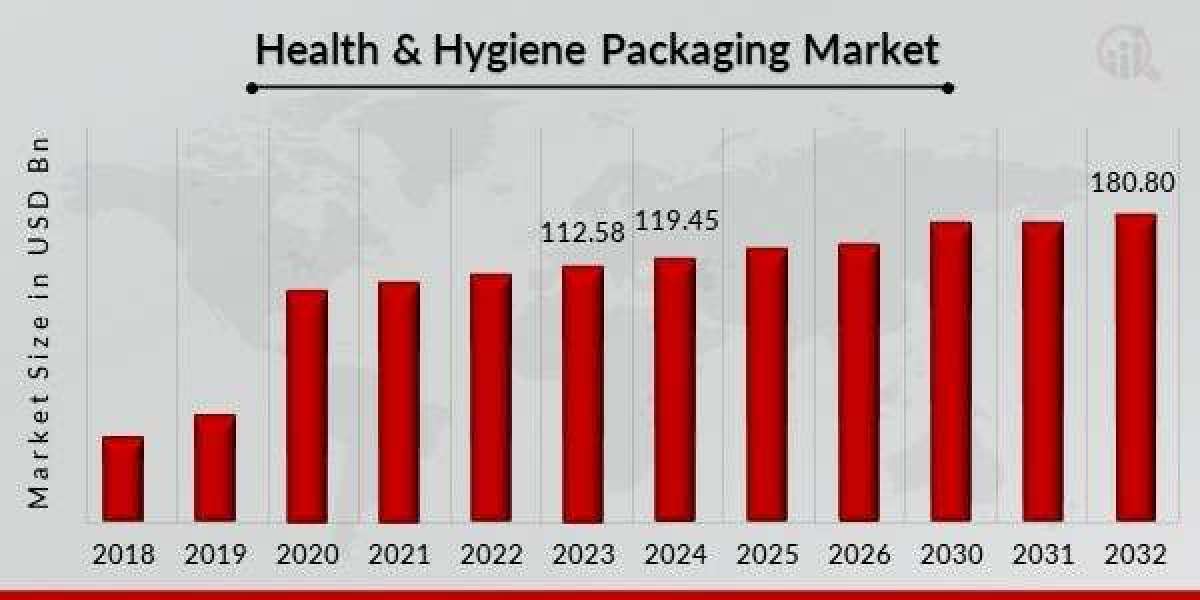

- Packaging: It is used in packaging applications, such as shopping bags, food packaging, and protective wraps, offering strength and durability.

- Furniture and Bedding: The fabric is used in furniture and bedding as mattress covers, pillow shells, and upholstery backing, offering durability and comfort.

- Filtration: It finds applications in filtration, such as air filters, liquid filters, and face masks, effectively trapping particles.

- Automotive: It is used in automotive applications for interior trim, sound insulation, and seat components, leveraging its durability and acoustic properties.

Gujarat: A Hub of Innovation and Manufacturing

Gujarat, a state in India, has emerged as a significant hub for the production and export of PP spunbond nonwoven fabric. The state's favorable industrial policies, availability of raw materials, skilled labor, and strategic location have attracted numerous manufacturers and exporters. The presence of Spunbond nonwoven manufacturers in Gujarat and a strong network of PP nonwoven fabric suppliers in India has boosted the industry, making it a competitive player in the global market. These manufacturers cater to diverse needs, providing a wide range of fabric specifications and customization options. The strategic location also facilitates access to ports, which makes it convenient for Spunbond non woven fabric exporters in Gujarat to efficiently supply their products to markets worldwide.

The Future of ShieldWeave: Innovations and Sustainability

The PP spunbond nonwoven fabric industry is constantly evolving, with manufacturers striving for further innovations and sustainability improvements. Research and development efforts are focused on:

- Developing new polymers and blends: To enhance the fabric's performance and expand its applications.

- Improving manufacturing processes: To increase efficiency, reduce waste, and lower costs.

- Creating eco-friendly products: Using recycled PP, biodegradable polymers, and sustainable manufacturing practices to minimize environmental impact.

- Enhancing functional properties: To incorporate features such as antimicrobial, anti-static, and UV protection, which are increasingly in demand.

Conclusion: Embracing the Power of ShieldWeave

PP spunbond nonwoven fabric has established itself as a versatile and essential material across industries. Its unique combination of strength, breathability, water resistance, and cost-effectiveness makes it an ideal choice for a wide range of applications. With its adaptability, affordability, and contribution to sustainability, this fabric is set to play a pivotal role in shaping the future of textiles, and its production hub in Gujarat continues to drive its progress and global presence. As technology advances and consumer preferences evolve, PP nonwoven fabric suppliers in India will continue to evolve, offering even greater value to businesses and consumers.

Frequently Asked Questions (FAQ)

- What is the difference between PP spunbond and other nonwoven fabrics?

PP spunbond nonwoven fabric is made through a unique process that creates a strong, durable fabric from continuous PP filaments. Other nonwoven fabrics may be made from different fibers or using alternative bonding methods, which can influence their properties and suitability for certain applications. For instance, needle-punched nonwoven is a mechanical bonding method where needles entangle the fibers, while wetlaid nonwoven uses a slurry of fibers in water to create the fabric. - Can PP spunbond nonwoven fabric be customized to specific requirements?

Absolutely! Manufacturers offer a high degree of customization. You can choose the fabric's weight (GSM - grams per square meter), width, color, and other features like UV resistance, anti-static properties, or special finishes. The bonding method and fiber diameter can also be adjusted to modify the fabric's strength, softness, and permeability. - Is PP spunbond nonwoven fabric environmentally friendly?

PP itself is recyclable, so the fabric can be recycled. The recyclability of the fabric can vary depending on its use and how it's bonded. Some manufacturers are also focusing on using recycled PP or incorporating biodegradable materials into their production processes.