The Rise of Advanced Medical Seals Innovations in 2025

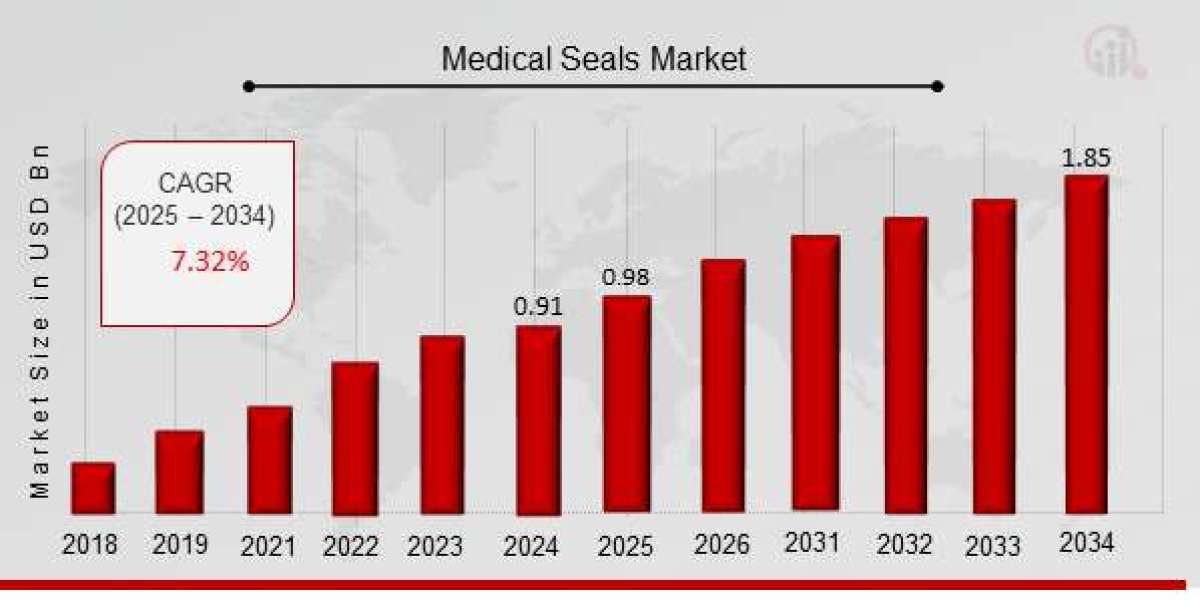

The healthcare industry is continuously evolving, driven by new technologies and innovations aimed at improving patient safety, treatment outcomes, and operational efficiency. One area that has seen remarkable advancements in recent years is the medical seals market. Medical seals play a crucial role in ensuring the sterility, security, and integrity of medical products and equipment. As we move into 2025, the demand for advanced medical seals is expected to surge, driven by innovations in materials, manufacturing processes, and regulatory requirements. This blog will explore the rise of advanced medical seals and the trends that are shaping the market in 2025.

The Importance of Medical Seals in Healthcare

Medical seals are used across a wide range of healthcare products, including drug packaging, medical device sterilization, and the sealing of sterile surgical instruments. The primary function of these seals is to protect medical products from contamination, preserve their integrity during transportation, and maintain the sterility of critical supplies until they are used in a clinical setting. Without reliable seals, the safety and efficacy of medical products would be compromised, potentially putting patients' health at risk.

Additionally, medical seals are often used in packaging to prevent tampering, ensuring that products have not been altered before they reach their intended users. This is particularly important in the context of pharmaceuticals and high-risk medical devices, where even minor alterations or contamination can lead to severe consequences.

Key Drivers of Innovation in Medical Seals

- Rising Demand for Sterile Packaging

The growing emphasis on sterility and hygiene in the medical field is one of the major drivers of innovation in the medical seals market. As healthcare providers continue to focus on infection control and patient safety, the demand for packaging solutions that provide a higher level of protection against contaminants is increasing. This has led to the development of advanced seals made from innovative materials that offer superior barrier properties and longer-lasting performance.

Materials such as medical-grade silicone, elastomers, and advanced polymers are being used to create seals that provide enhanced durability, flexibility, and resistance to environmental factors like heat, moisture, and chemical exposure. These materials help ensure that medical devices and pharmaceutical products maintain their integrity throughout their lifecycle.

- Technological Advancements in Seal Manufacturing

Advancements in manufacturing processes have also contributed to the rise of advanced medical seals. Techniques like injection molding, laser welding, and ultrasonic sealing are being increasingly used to create seals that are not only more effective but also more efficient to produce. These methods allow manufacturers to create seals with higher precision, ensuring better fit and function for medical devices and packaging.

Furthermore, 3D printing technologies are making their mark on the medical seals market, enabling the production of customized seals tailored to specific medical devices or unique packaging needs. This customization allows for more effective sealing solutions, ensuring a higher level of security and integrity for sensitive medical products.

- Increased Regulatory Pressure

Regulatory bodies such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) have raised their standards for medical device and drug packaging in recent years, pushing manufacturers to develop more advanced sealing technologies. Compliance with these stringent regulations is crucial for medical product manufacturers who want to maintain market access and avoid costly recalls or legal issues.

As regulations surrounding packaging integrity, sterility, and safety continue to evolve, medical seal manufacturers must innovate to meet these requirements. This includes the development of seals that can withstand extreme sterilization processes (such as gamma radiation or steam autoclaving) without losing their effectiveness. Additionally, there is growing demand for tamper-evident seals, which help provide an added layer of security by clearly showing whether a product has been compromised before use.

- Sustainability and Eco-Friendly Materials

As environmental concerns continue to grow, there is increasing pressure on all industries, including healthcare, to adopt more sustainable practices. The medical seals market is no exception, and there is a growing trend toward using eco-friendly materials in seal manufacturing. Biodegradable, recyclable, and non-toxic materials are being explored as alternatives to traditional plastics and polymers, reducing the environmental impact of medical packaging.

In response to this demand, some manufacturers are already producing medical seals made from plant-based polymers or materials derived from renewable resources. This trend is expected to accelerate in 2025 as both consumers and healthcare organizations push for more sustainable options in medical products and packaging.

Trends Shaping the Medical Seals Market in 2025

- Smart Seals and Tracking Technologies

As the healthcare industry continues to embrace digital transformation, the integration of smart technologies into medical seals is becoming a key trend. Smart seals that incorporate radio-frequency identification (RFID) or near-field communication (NFC) capabilities can provide real-time data about the status of medical products. These seals can track product movements throughout the supply chain, ensuring that products have not been tampered with or exposed to conditions that could compromise their safety.

Additionally, smart seals can be programmed to provide alerts when products reach expiration dates or if packaging integrity is compromised. This can enhance inventory management and improve patient safety by preventing the use of expired or potentially contaminated products.

- Increased Focus on Patient-Centric Solutions

In 2025, medical seal manufacturers are likely to place more emphasis on creating patient-centric solutions that align with the evolving needs of healthcare providers and patients. This includes developing seals for home healthcare products, such as wound care or drug delivery systems, that ensure the safety and ease of use for patients outside of hospital settings.

For example, easy-to-open seals for home-use medical devices or single-use packaging for pharmaceuticals can improve the user experience for patients, reducing the risk of errors or contamination. These innovations are particularly important as the healthcare system shifts toward more personalized and home-based care.

Conclusion

As the healthcare landscape evolves, so too does the role of medical seals in ensuring the safety, security, and integrity of medical products. From rising demand for sterility to advancements in manufacturing techniques and regulatory pressures, the medical seals market is seeing significant innovation. With the continued focus on patient safety, sustainability, and smart technologies, the future of medical seals looks promising, and the industry is poised to experience continued growth in 2025 and beyond.