Global Conveying Equipment Market Set to Reach USD 65.74 Billion by 2030

Market Estimation & Definition

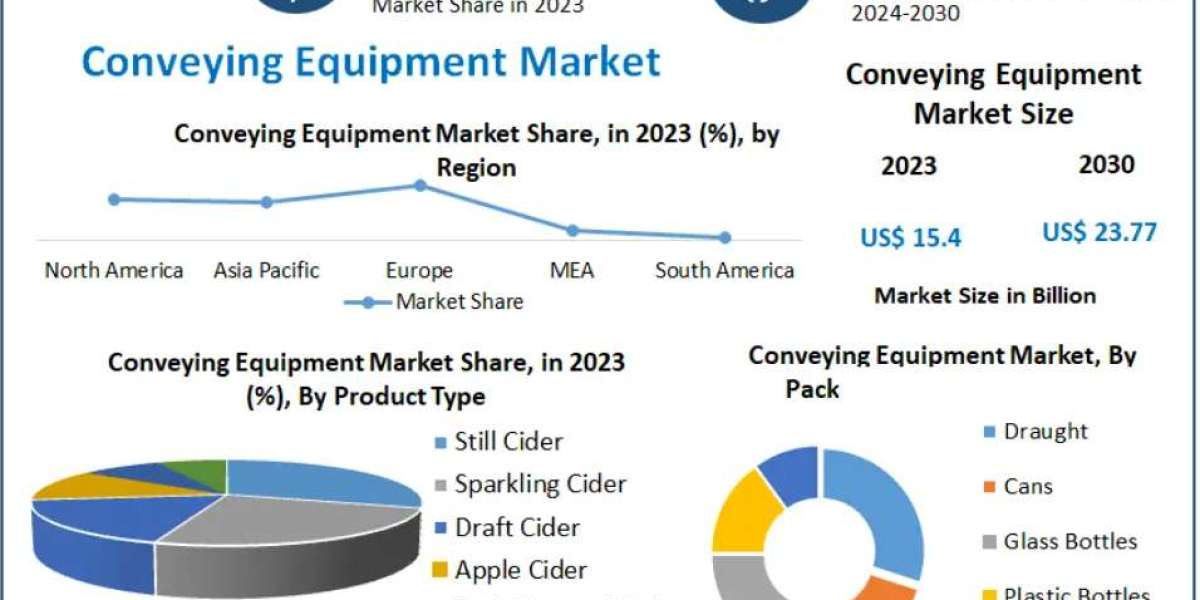

The Global Conveying Equipment Market was valued at approximately USD 51.64 billion in 2023 and is projected to reach USD 65.74 billion by 2030, expanding at a steady CAGR of 3.51% during the forecast period. Conveying equipment refers to a broad range of mechanical handling systems that efficiently transport materials and goods from one location to another. These systems include belt conveyors, roller conveyors, overhead conveyors, and more specialized solutions designed for specific industries. They are vital for automating material handling processes across manufacturing, warehousing, mining, and logistics sectors, improving productivity and safety while reducing operational costs.

Unlock critical market insights by exploring the sample via the link @https://www.maximizemarketresearch.com/request-sample/54236/

Market Growth Drivers & Opportunities

Several key drivers are pushing the growth of the conveying equipment market globally:

Rise in Automation: Industries are increasingly adopting automated solutions to boost efficiency, reduce labor dependency, and minimize human error. Conveying systems play a crucial role in achieving seamless material flow and production processes.

Boom in E-commerce and Warehousing: The rapid growth of online retail has led to the expansion of warehouses and fulfillment centers. This, in turn, drives the demand for scalable and high-speed conveying equipment to handle growing product volumes efficiently.

Focus on Worker Safety and Efficiency: Conveyors reduce manual handling of materials, thereby improving worker safety and lowering the risk of injuries. Companies are also investing in ergonomic designs to enhance operational comfort.

Integration of Smart Technologies: The incorporation of IoT, automation controls, and AI-powered diagnostics in modern conveying systems allows real-time performance monitoring, predictive maintenance, and energy optimization, opening new opportunities for market growth.

What's Next: New Developments That Will Influence the Future

The market for conveying equipment is changing as a result of the following major trends:

Smart and Modular Conveying Systems: Manufacturers are providing modular solutions that are more flexible and scalable and can be readily expanded or altered in accordance with operating requirements.

Sustainable Conveyor Solutions: In line with international sustainability goals, there is a growing focus on environmentally friendly and energy-efficient conveyor systems, such as those that use recyclable materials and low-energy motors.

Advanced Material Innovations: Belts and rollers made of lighter but stronger materials are more durable, produce less noise, and extend the life of systems.

Integration with Robotics and AI: Conveyors and robotics are increasingly working together to improve efficiency and throughput, particularly in industries like food processing and logistics. This collaboration enables accurate sorting, routing, and handling.

Segmentation Analysis

Based on the provided segmentation:

By Product:

Bulk Handling: Used for large-volume material transport, especially in mining, construction, and agriculture.

Unit Handling: Designed for discrete items such as packages, cartons, and pallets; widely used in manufacturing and e-commerce.

Parts and Attachments: Components such as belts, rollers, chains, and frames that support customized conveyor setups.

By Type:

Belt Conveyors: The most common type, suitable for various applications including packaging and distribution.

Roller Conveyors: Often used in material accumulation and storage areas.

Pallet Conveyors: Built for transporting heavy palletized goods.

Overhead Conveyors: Ideal for hanging items such as garments or auto parts in production lines.

Others: Includes pneumatic, screw, and vibrating conveyors used in specialized sectors.

By End User:

Automotive

Airport

Retail

Food and Beverages

Mining

Electronics

Others

Get a closer look at the game-changing products driving success : https://www.maximizemarketresearch.com/request-sample/54236/

Country-Level Analysis

USA: The United States dominates the North American market for conveying equipment due to its strong manufacturing sector, advanced logistics infrastructure, and rapid warehouse automation. The country is also witnessing increased investments in smart warehouses and fulfillment centers, which significantly boost demand for advanced conveyor systems.

Germany: As a hub for automotive and industrial machinery, Germany is a major market for conveying equipment in Europe. The country's emphasis on technological advancement, precision engineering, and Industry 4.0 adoption positions it as a leading contributor to the European market. The push for energy efficiency and automation in German manufacturing also creates sustained demand for intelligent conveyor systems.

Commutator (Competitive) Analysis

The conveying equipment market is highly competitive and features a mix of global players and regional specialists. Key companies are focusing on:

Product Innovation: Launching smart conveyors with integrated sensors, automated diagnostics, and enhanced safety features.

Expansion Strategies: Strengthening global footprint through mergers, acquisitions, and partnerships to enter emerging markets.

Customization & Flexibility: Offering tailored solutions for niche industries with specific needs, such as pharmaceuticals, food processing, or mining.

Sustainability: Developing energy-efficient systems and leveraging eco-friendly designs to align with environmental regulations and corporate ESG goals.

Top players are leveraging technology-driven approaches and R&D investments to maintain market leadership, while new entrants are focusing on modular, cost-effective, and compact conveying systems to tap into small and mid-sized businesses.

Press Release Conclusion

The global conveying equipment market is poised for consistent growth through 2030, driven by the expanding need for automation, smart material handling solutions, and operational efficiency across sectors. With rapid advances in technology, increased industrial digitization, and the growing demand for sustainable systems, conveying equipment will remain an integral part of the global supply chain infrastructure. Stakeholders should capitalize on evolving trends such as modularity, smart integration, and eco-efficiency to stay competitive and address the changing needs of modern industry.