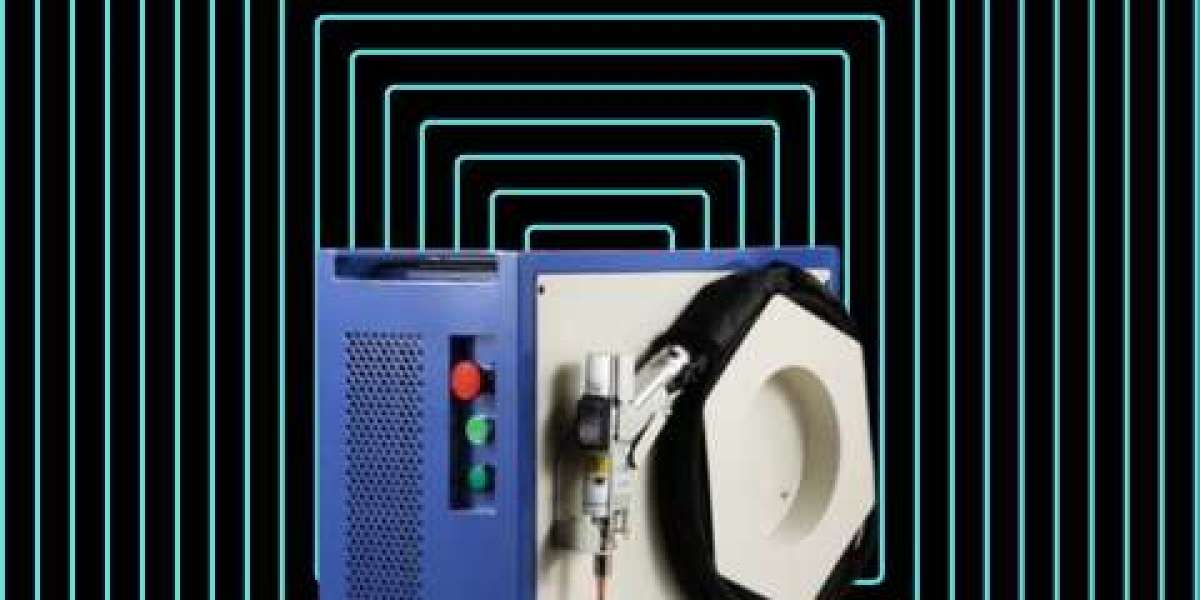

When it comes to precision, speed, and industrial adaptability, the China Laser Welder by LaserChina stands tall as a game-changer in modern metal processing. Built with innovation at its core, LaserChina has grown to become a trusted name among global manufacturers, offering high-performance laser welding solutions that outperform traditional methods in accuracy, durability, and cost-efficiency.

Why Choose LaserChina's Laser Welders?

LaserChina combines engineering excellence, user-focused design, and advanced laser technology to deliver top-tier machines. These welders are favored by industries such as automotive, aerospace, medical devices, electronics, and metal fabrication, offering:

Contactless, ultra-precise welding

Minimal thermal distortion

Low maintenance and high uptime

Compatibility with diverse metals

Let’s break down the core advantages that make LaserChina a frontrunner in the laser welding space.

Comparative Table: LaserChina vs Traditional Welding

| Feature | LaserChina Laser Welder | Traditional Welding |

|---|---|---|

| Welding Speed | Up to 4x faster | Slower |

| Heat Affected Zone (HAZ) | Minimal | Significant |

| Weld Strength | High and uniform | Varies |

| Material Compatibility | Wide range | Limited |

| Maintenance | Low | High |

| Automation Integration | Seamless | Complex |

Advanced Features of LaserChina Laser Welders

1. Fiber Laser Technology

Utilizing cutting-edge fiber lasers, these machines offer deeper penetration, finer control, and longer service life. The stable beam ensures consistent welds even in continuous operation environments.

2. User-Friendly Interface

LaserChina machines come with an intuitive touchscreen interface, enabling precise control of power, frequency, and speed settings. Designed with operators in mind, it reduces training time significantly.

3. AI-Driven Precision Control

Select models feature AI-enhanced welding paths, allowing for real-time feedback and self-correction to ensure optimal weld quality every time.

Use Cases Across Industries

Automotive Manufacturing: Ideal for battery pack welding, gear parts, and structural components where strength and lightness are essential.

Electronics & PCB Repair: LaserChina’s micro-welding solutions allow precise spot welding for delicate electronics.

Medical Devices: Clean and sterile welds for instruments and implants, meeting strict industry standards.

Metal Furniture & Art: Seamless and aesthetic welds that require minimal finishing, saving time and costs.

FAQs About China Laser Welder by LaserChina

Q1: What metals can be welded using LaserChina machines?

A: Stainless steel, aluminum, copper, brass, carbon steel, and more. Its versatility makes it ideal for multi-material environments.

Q2: How difficult is the setup process?

A: LaserChina systems are plug-and-play with guided configuration tools. Setup is simplified to minimize downtime.

Q3: Can LaserChina welders be integrated into existing automation lines?

A: Yes. They support robotic arms, CNC systems, and custom automation workflows.

Q4: Is training or after-sales support available?

A: Absolutely. LaserChina offers remote guidance, video tutorials, and in-person training packages for all customers.

Q5: How does it compare in terms of operational cost?

A: Operating costs are lower due to energy efficiency, minimal consumables, and reduced rework or waste.

What Makes LaserChina a Trusted Manufacturer?

LaserChina is not just another equipment provider. With over a decade of R&D and international recognition, it offers:

ISO-certified manufacturing standards

On-demand customization

24/7 multilingual technical support

Proven track record in over 50 countries

Their commitment to engineering reliability, real-world performance, and responsive service has earned them recognition among manufacturers from Asia to Europe and the Americas.

Real-World Performance Metrics

| Metric | Performance |

|---|---|

| Accuracy | ±0.02 mm |

| Power Range | 500W – 3000W |

| Daily Runtime | 16–24 hours |

| Maintenance Cycle | 6 months |

| Typical ROI Period | 6–12 months |

Final Thought

If your manufacturing operation values precision, durability, and high-speed performance, the China Laser Welder from LaserChina is a serious contender. Built for demanding industrial needs, it brings next-gen laser welding into your production line with minimal fuss and maximum return on investment.