Laser cleaning machines have emerged as a game-changer in surface preparation, rust removal, and industrial cleaning processes. With zero chemicals, minimal waste, and high precision, these tools are replacing outdated sandblasting and chemical stripping methods. But the key question most buyers ask is: What’s the real cost of a laser cleaning machine, and what factors influence it?

This detailed guide breaks down laser cleaning machine price, features, and buying considerations to help you make informed choices in 2025.

What is a Laser Cleaning Machine?

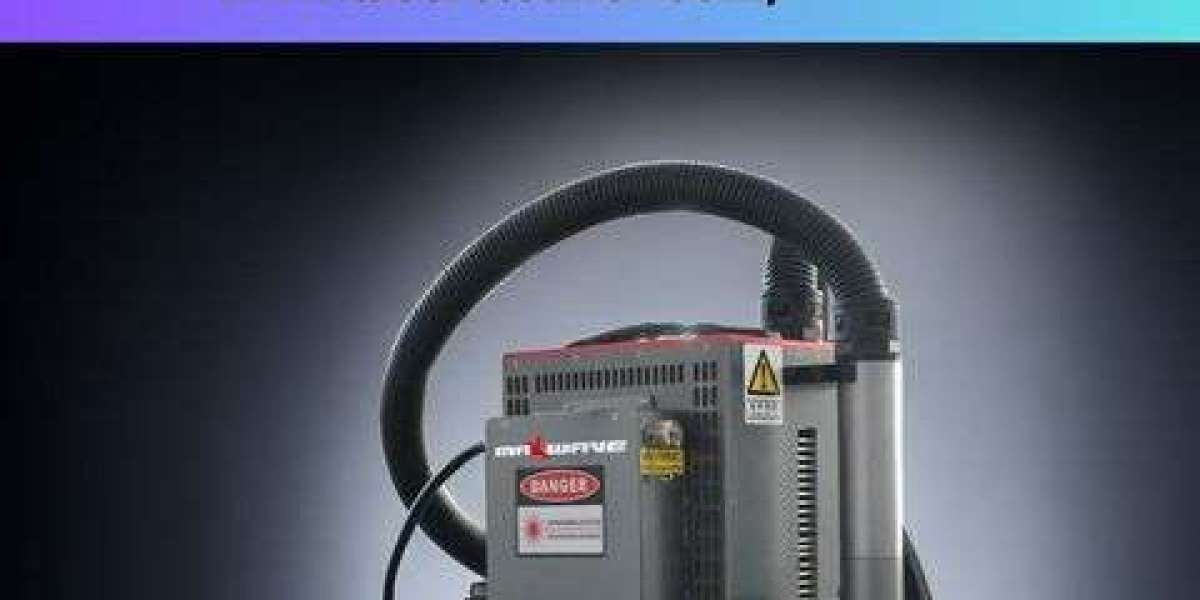

A laser cleaning machine uses concentrated laser beams to remove unwanted materials—like rust, paint, oil, and oxides—from a surface. This method is non-contact, eco-friendly, and highly efficient, making it ideal for aerospace, automotive, electronics, and restoration industries.

Laser Cleaning Machine Price Overview (2025)

| Laser Power | Application | Approx. Price (USD) |

|---|---|---|

| 50W–100W | Light cleaning, lab use | $4,000 – $8,000 |

| 200W–300W | Industrial rust removal | $9,000 – $18,000 |

| 500W | Mid-size metal cleaning | $18,000 – $25,000 |

| 1000W+ | Heavy-duty industrial usage | $28,000 – $60,000 |

Note: Prices vary based on brand reputation, optical configuration, control system, and automation compatibility.

What Affects the Price of a Laser Cleaning Machine?

Several variables impact pricing:

Laser Power Output: Higher wattage means faster and deeper cleaning.

Laser Type: Fiber lasers (most common) are more efficient and long-lasting than CO₂ or YAG.

Cooling System: Air-cooled models cost less but are suited for lower power ranges.

Automation Integration: Machines compatible with robotic arms or CNC systems cost more.

Portability: Handheld units tend to be more affordable than fully automated stations.

Software & Interface: Touchscreen UIs, AI detection, and programmable logic raise the cost.

Brand Trust: Manufacturers with established reputations charge premiums but offer better service, spare parts, and support.

Features to Look For in a Laser Cleaning Machine

When comparing models by price, also evaluate core features:

Adjustable Laser Frequency & Pulse Duration

Anti-Reflection Protection

Replaceable Laser Heads

Dust Filtration Systems

Intelligent Safety Shutoff

Industries Benefiting from Laser Cleaning Technology

Automotive: Frame degreasing, paint removal, weld prep

Aerospace: Oxidation cleaning, precision coating removal

Manufacturing: Mold cleaning, tool refurbishing

Cultural Restoration: Non-destructive graffiti or statue cleaning

Electronics: PCB surface treatment, oxide removal

Real-World Use Cases

A metal fabrication shop in Ohio reported saving 40% in cleaning costs after switching to a 1000W laser cleaner.

A heritage preservation group used a 200W unit to safely clean a 17th-century sculpture without abrasives.

Automobile manufacturers now integrate 500W laser cleaners into automated assembly lines to remove rust from undercarriages before welding.

FAQs: Laser Cleaning Machine Pricing & Usage

Q1: Can I rent instead of buying a laser cleaner?

A: Yes, rentals range from $200 to $800/day depending on power and portability.

Q2: How long do these machines last?

A: Most fiber laser systems have a lifespan of 80,000–100,000 hours, making them a long-term investment.

Q3: Is training required?

A: Minimal training is needed. Most machines come with user-friendly interfaces, though proper safety protocols are essential.

Q4: Are handheld units effective for industrial use?

A: Yes, especially for spot treatments or smaller parts, though automated models are better for large-scale operations.

Q5: Is laser cleaning environmentally safe?

A: It’s one of the greenest cleaning methods—no solvents, minimal emissions, and compliant with global sustainability standards.

Tips to Maximize ROI on Your Laser Cleaning Machine

Choose the right power-to-task ratio—don’t overspend on wattage you won’t use.

Invest in machines with replaceable parts to reduce long-term costs.

Buy from suppliers that offer in-country support and training.

Evaluate total cost of ownership, not just the upfront price.

Final Thought

Laser cleaning machines aren't just tools—they’re long-term assets for industries aiming to modernize maintenance and reduce environmental impact. As prices decrease and innovation continues, more sectors will adopt this powerful technology.