Safety is one of the most important factors when it comes to automotive design, and seat belts play a central role in protecting passengers. At the core of every seat belt system is the Car Seat Belt Webbing, a strong woven material designed to withstand extreme forces during sudden stops or collisions. Understanding its function, materials, and applications can help consumers and manufacturers appreciate why it is such a vital part of modern vehicles.

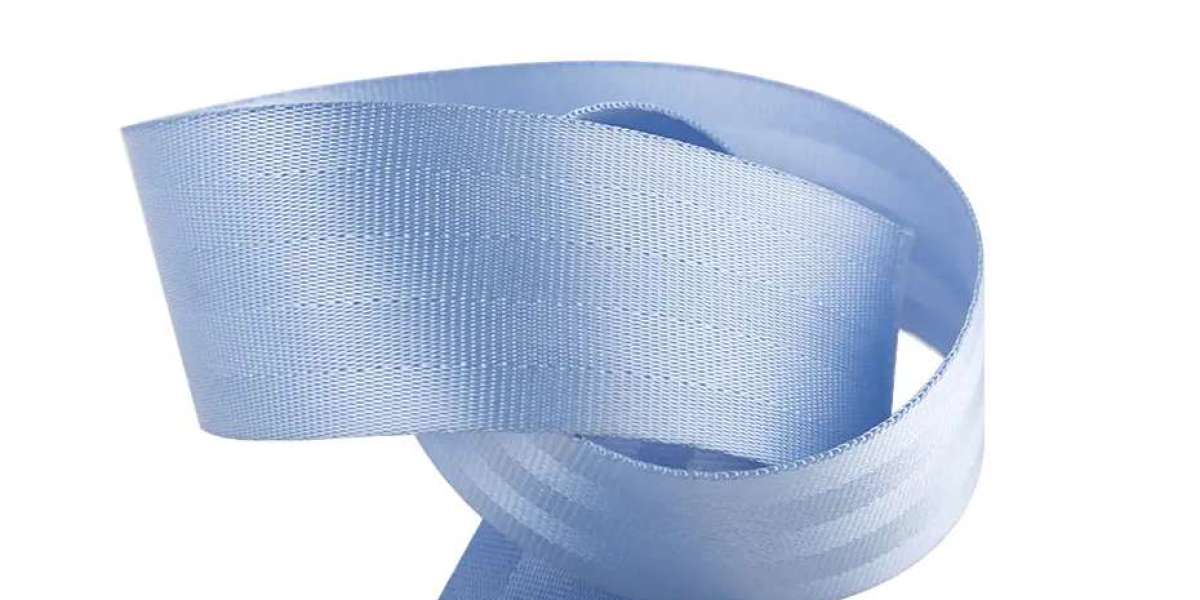

The Car Seat Belt Webbing is typically made from high-strength polyester fibers. This material is chosen for its durability, flexibility, and resistance to wear. Unlike ordinary textiles, the webbing used in seat belts must handle substantial loads while still maintaining comfort for passengers. Its special weave structure provides both strength and slight elasticity, which allows it to absorb energy in the event of an accident. Without reliable Car Seat Belt Webbing, the effectiveness of the entire restraint system would be compromised.

One of the key features of Car Seat Belt Webbing is its resistance to environmental conditions. Since vehicles are exposed to heat, cold, humidity, and ultraviolet radiation, the webbing must be treated to resist fading, fraying, and weakening over time. Manufacturers often apply protective coatings or finishes to ensure the webbing maintains its integrity throughout the life of the vehicle. This ensures that Car Seat Belt Webbing continues to function properly even after years of use.

The design of the webbing also considers comfort. Passengers wear seat belts for extended periods, so the Car Seat Belt Webbing must feel smooth against the skin while maintaining its strength. Advances in textile engineering have allowed for webbing that balances toughness with user comfort. Modern production methods also allow for different colors and patterns, enabling vehicle brands to match their interior designs without compromising safety standards.

Testing is another critical aspect of Car Seat Belt Webbing production. Each batch of webbing must undergo strict evaluations, including tensile strength tests, abrasion resistance, and flame retardancy checks. These procedures guarantee that the material can perform reliably in real-world conditions. Car manufacturers depend on consistent quality, which is why Car Seat Belt Webbing suppliers must adhere to international safety regulations and automotive standards.

In addition to passenger cars, Car Seat Belt Webbing is also widely used in buses, trucks, and specialized vehicles. The requirements may vary depending on the type of vehicle and seating configuration, but the core function remains the same: securing occupants safely. Some heavy-duty applications may require wider or thicker webbing, while luxury vehicles may prioritize added comfort and aesthetic finishes. This versatility highlights the adaptability of Car Seat Belt Webbing to meet different industry demands.

Sustainability has also become an important consideration in recent years. Many manufacturers are exploring ways to make Car Seat Belt Webbing more environmentally friendly by using recycled polyester or adopting energy-efficient production methods. These efforts not only reduce environmental impact but also align with the automotive industry's growing commitment to greener practices.

Car Seat Belt Webbing is more than just a piece of fabric; it is a critical safety component that protects lives every day. With its strong construction, resistance to harsh conditions, and adaptability to various vehicle types, it continues to be a reliable solution for passenger safety. As automotive technology evolves, Car Seat Belt Webbing will remain a cornerstone of occupant protection, combining durability, comfort, and innovation in one essential material.